Storage Systems

Store and display textiles under the environmental conditions described above.

Flat Storage

Store textiles as flat as possible with minimal folding. This provides maximum relaxation for fibres while avoiding weight-bearing stresses. If folding is unavoidable, support folds with a sausage of crumpled acid-free tissue. This minimises damage along the folds, the points at which there is most stress on the fibres. While it is generally preferable not to layer items to minimise creases and folds, small light weight two dimensional textiles can be interleaved with acid-free tissue with several placed on top of each other (Figure 4).

Figure 4: Box packed with flat textiles (two dimensional storage).

Large metal map cabinets and low profile acid-free cardboard or polypropylene boxes provide excellent storage media for flat textiles with minimum folding. In addition to allowing for easy transportation, these boxes provide light and dust protection.

Support three dimensional artefacts with crushed acid-free tissue and lightly fill the surrounding area within the box with rounded balls of tissue. This prevents the textile slumping in the box when it is moved (Figure 5).

Figure 5: Christening gown and accessories supported with crushed acid-free tissue and blocked in with balls of tissue (three dimensional storage).

Rolled Storage

To save space, some strong (and generally larger) flat textiles may be rolled onto acid-free cardboard tubes. Note the following points if considering rolled storage:

- rolled storage is generally not appropriate for painted textiles or for those that have been treated with adhesives;

- use tubes appropriate to the size of the artefact, but the larger the diameter the better;

- the tube should be at least 60 mm wider than the textile to be rolled and up to 200 mm wider for larger artefacts;

- if large tubes are not available, the effective diameter of smaller tubes can be increased by wrapping bubble wrap around the outside;

- if there is no option but to use non acid-free cardboard tubing, isolate the textile from the tube with polyester (Mylar) or polyethylene sheeting and acid-free paper; and

- if the use of PVC tubing cannot be avoided for the long-term storage of textiles, seal the PVC with water-based polyurethane lacquer and use a barrier of polyester (Mylar) between the textile and the tube.

Roll textiles to minimise stresses on the textile and to protect it against adverse environmental conditions. To do this:

- place the textile face down and roll it along either the warp or the weft;

- while rolling, keep the textile firm, though not stretched, and interleaf it with acid-free tissue as it is being rolled;

- when rolling textiles that are either lined or have a second layer, take care to ensure that the inner layer does not become bunched or excessively creased;

- cover the rolled textile with a pre-washed white cotton/polycotton fabric or Tyvek® and tie it with cotton tape (but not too tightly);

- store rolled textiles by suspending them in a frame using a rod passed through the centre of the roll;

- do not allow rolled textiles to touch each other;

- cover the rack of rolled textiles with a pre-washed, lightweight, tightly woven fabric to give the rolled textiles protection from light and dust; and

- identify each textile by tying labels onto each tube, making sure that the labels are all at the same end.

Rolled Storage for Flags

The following system has been developed for the storage of suites of robust flags. It is not suitable for fragile flags. The system has the added advantage that a flag can be examined and re-rolled without the storage components going astray.

- cut a standard 68 mm diameter,acid-free tube, 60 mm longer than the maximum flag height;

- stick a square of double sided tape on each end to secure the roll in the Tyvek® channel;

- prepare a Tyvek® 1443R sheet the size of the flag plus the 60 mm height allowance and with allowance in the length to make a tube casing at one end and tie off at the other end (usually about 600 mm more than the width of the flag);

- machine sew the casing allowance at one end of the Tyvek® and an appropriate number of cotton tape ties at the other end. All rolls require at least two ties, but otherwise the ties should be evenly spaced about 400 mm apart;

- label the outside of the tie off end of the Tyvek® with the registration number and flag information;

- place the tube into the casing and remove the cover of the double sided tape to hold the Tyvek® in place;

- roll the flag with the fly first and hoist last, carefully flattening the flag as it is rolled;

- fold the hoist rope in at the end;

- place any metal fittings in small zip lock polyethylene bags;

- tie off (not too tight) with the cotton ties to hold the roll; and

- store rolls in a single layer. Do not stack rolls on top of each other.

Hanging Storage for Costumes

Only costumes in excellent condition should be considered for hanging storage. Use boxes to store weakened costumes or those that are heavily decorated. Pad costumes with acid-free tissue to minimise folds and creasing.

If costumes are to be hung, follow these general principles:

- pad and cover the hanger to fit the costume;

- spread the weight of the costume onto the hanger;

- make a protective cover to fit over the costume; and

- hang the costume in a tall cupboard that allows for full suspension without bunching.

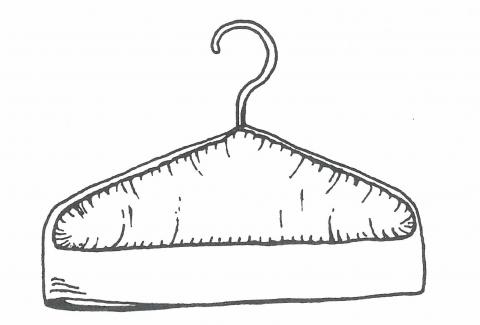

The hanger must be smaller than the costume and padded in the form of shoulders to fit the costume. Polyester wadding (e.g. Dacron) may be used to firmly fill the shape. By padding the hanger the weight of the costume is spread over a larger area, thereby reducing the load-bearing stress on the shoulders. Cover the padded hanger with pre-washed cotton fabric (Figure 6).

Figure 6: Fabric covered padded hanger.

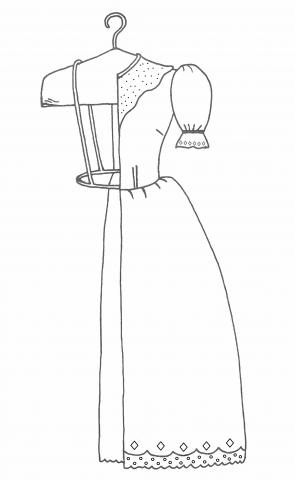

For tailored jackets, shape Ethafoam® 220 to be slightly smaller than the shoulders of the jacket and hot glue it onto both sides of a wooden coat hanger. Cover this with polyester wadding (Dacron) and pre-washed white cotton/polycotton fabric or Tyvek®. It is important that the final padded coat hanger is the correct size and shape to support the jacket shoulders. If it is not adequately supported, the weight of the costume will cause damage in the long term. When hanging costumes, spread the weight of the costume onto the hanger, but don’t have the weight only on the shoulders. For dresses sew cotton tapes to the structurally strong parts inside at the waist. Tie these tapes to the hanger to take the weight of the skirt off the bodice (Figure 7). Alternatively, and especially if the waist is weakened, sew a reinforcing cotton ‘hoop’ to the inside of the waist. Attach this to the padded hanger with cotton straps, thereby ensuring a more even weight distribution while concurrently strengthening the waist.

Figure 7: Hanging storage – padded hanger with cotton straps.

Each costume should have its own removable and washable cover. Make covers from light, tightly woven fabrics such as polyester lining or Tyvek®. Avoid fabrics such as cotton that have a tendency to cling or that have a strong frictional hold. Sew the cover so there is enough space inside for the costume to fit without restricting it. It must loosely cover the entire costume and have a closure at the bottom. Ensure the cover can be put on the costume from the side rather than over the top.

The cupboard in which costumes are hung must allow them to be fully suspended. As many dresses have trains, it will be necessary to have very tall storage cupboards. The train should not be crumpled at the bottom of the cupboard. Minimise crushing by not overfilling cupboards used for hanging textiles.